IoT Monitoring for Industries

The global internet of things (IoT) market in manufacturing was valued at USD 221.18 billion in 2019 and is expected to reach USD 575.36 billion by 2025

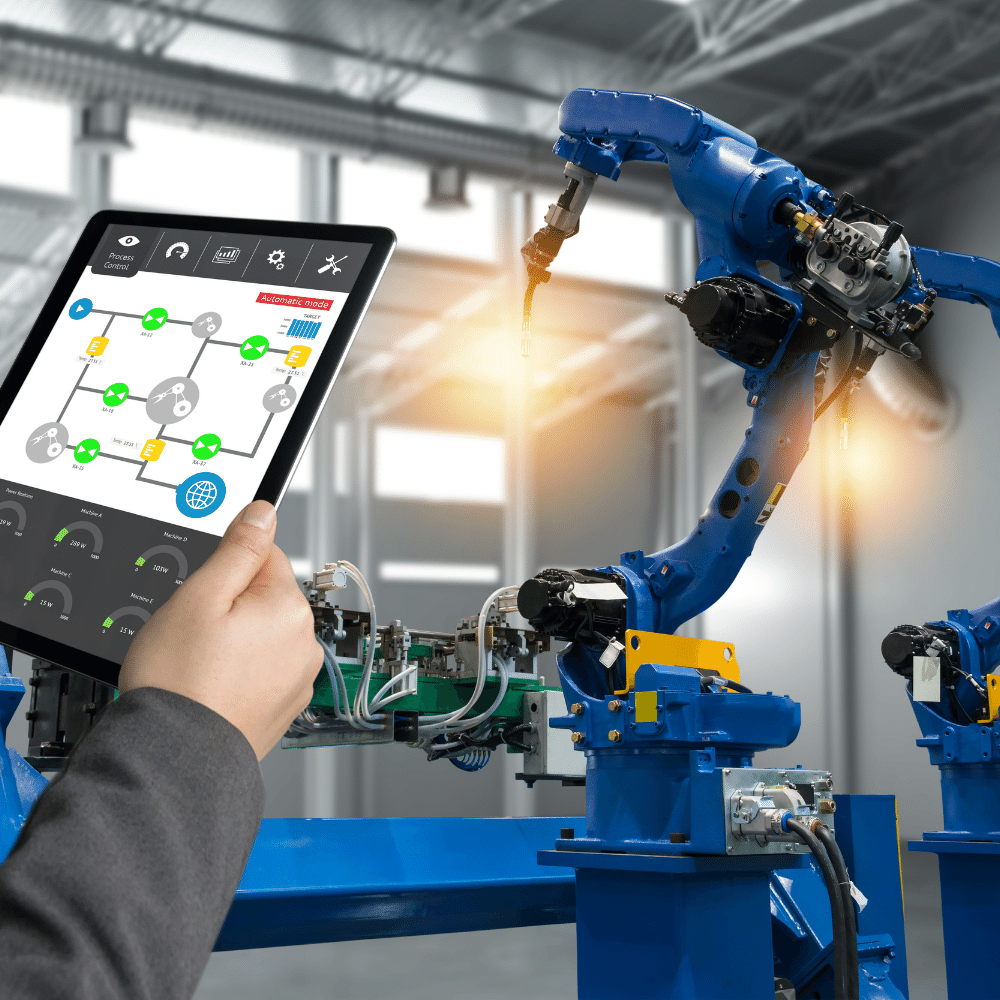

Manufacturing and production of companies is a highly complex interconnected value chain. This process generates lots of data. Most of the machines in current factories have been used for a long time and upgrading old machines is a capital intensive process. Therefore the present day smart systems face a bottle neck in capturing the generated data in manufacturing processes into computer systems simply because of the lack of practical method to make old machines into smart machines. Dashboards and business intelligence have become essential parts of decision making in today’s business environment. The data capturing and aggregation plays a major role in this process. Many factories has existing IT systems and the implemented device compatibility for APIs and different integrations is an area still most devices struggle achieve due to complexity of integration of different systems and cost involved.

ThingsNode is a device equipped with multiple communication channels to transmit data and operate even with very low power conditions. It has multiple interfaces to handle sensor inputs and outputs in industry environments complying with safety standards. Another successful implementation of ThingsNode in this area was completed with a blue chip apparel manufacturer in Katunayake. This manufacturing facility required to visualize the production output, downtime of machines and fault detection of machines. The sensor network was implemented with multiple devices as communication and data aggregation modules. The data is visualized with cloud application to the end user to display real time data of the production flow with 24X7 availability.